Structural Design & Detailing

We pride ourselves on using cutting edge resources to perform early detailing (“design-assist”) services while design documents are still being developed. This allows steel to be purchased and fabricated early, saving time and money in the project schedule and budget.

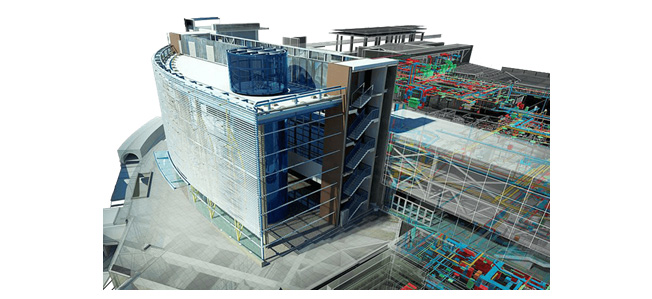

We utilize BIM to the fullest with model transfers between Revit, the steel detailing software, and Navisworks to help all design and construction team members identify and resolve problems ahead of time.

Our engineering group can produce shop drawings quickly and accurately whether your job is 10 tons or 5,000 tons by bringing together the best people, processes and technology to cycle through drawing approvals and respond to field conditions faster with carefully crafted solutions. Using the latest communication technologies we can make our Pristine office feel like it is right next door.

Our Core Team

All of our detailers have bachelor degree as engineers or architects.

All of our detailers have bachelor degree as engineers or architects.

Our drawing room supervisors have a combined 65 years of experience in construction management, engineering and steel detailing.

Our drawing room supervisors have a combined 65 years of experience in construction management, engineering and steel detailing.

We have a licensed professional engineer on site as well as consulting engineers for more extensive design reviews and calculations.

We have a licensed professional engineer on site as well as consulting engineers for more extensive design reviews and calculations.

We can contribute significantly to the constructability of design/build and fastrack projects.

We can contribute significantly to the constructability of design/build and fastrack projects.

Our Sample Projects

3D Modeling

3D modeling has become the industry wide standard and with the complex steel elements in today's structures, it is truly an incredible tool for all parties to be able to visualize the structure and get a feel for the project before ground break.

3D modeling has become the industry wide standard and with the complex steel elements in today's structures, it is truly an incredible tool for all parties to be able to visualize the structure and get a feel for the project before ground break.

3D RFI's are also generated from the model enabling the design issue at hand to be addressed accurately and efficiently the first time, with minimal turn-around time.

3D RFI's are also generated from the model enabling the design issue at hand to be addressed accurately and efficiently the first time, with minimal turn-around time.

At Intrax, our entire team utilizes the 3D modeling software from the inception of the stick model to connection design to project management to checking.

At Intrax, our entire team utilizes the 3D modeling software from the inception of the stick model to connection design to project management to checking.

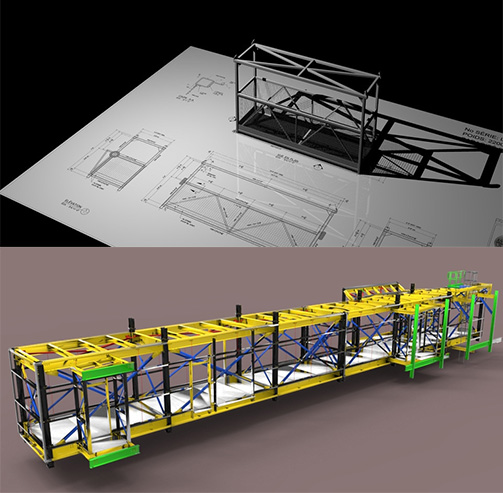

Detailing

The fabrication of structural and miscellaneous steel has advanced over the years with the modeling technology. Electronic data files such as dxf, cnc etc., are transmitted directly to the machinery and fabricated based upon the model parameters. Even with this advancement in technology, it remains imperative that the 2D drawings are presented with accuracy and quality both for the shop and for the field.

The fabrication of structural and miscellaneous steel has advanced over the years with the modeling technology. Electronic data files such as dxf, cnc etc., are transmitted directly to the machinery and fabricated based upon the model parameters. Even with this advancement in technology, it remains imperative that the 2D drawings are presented with accuracy and quality both for the shop and for the field.

Intrax works with both Imperial and Metric standards. Pristine also works closely with its clients to ensure their formats & methods of presentation are maintained and adhered to for use with their in-house requirements.

Intrax works with both Imperial and Metric standards. Pristine also works closely with its clients to ensure their formats & methods of presentation are maintained and adhered to for use with their in-house requirements.

Intrax is committed to the highest quality standards. The Pristine team is constantly kept abreast of industry changes to codes and practices with its numerous memberships to industry guiding organizations such as the American Institute of Steel Construction (AISC), the National Institute of Steel Detailing (NISD), the American Welding Society (AWS) & the Canadian Welding Bureau (CWB) to name just a few. Please review our Affiliates page for more information on our industry organizations.

Intrax is committed to the highest quality standards. The Pristine team is constantly kept abreast of industry changes to codes and practices with its numerous memberships to industry guiding organizations such as the American Institute of Steel Construction (AISC), the National Institute of Steel Detailing (NISD), the American Welding Society (AWS) & the Canadian Welding Bureau (CWB) to name just a few. Please review our Affiliates page for more information on our industry organizations.

BIM Coordination & Consulting

As the detailer, we can provide a “walk-through” Navisworks model for the contractor that is coordinated with the steel detailing model and all design team models

As the detailer, we can provide a “walk-through” Navisworks model for the contractor that is coordinated with the steel detailing model and all design team models

As the structural consultant, we can provide a BIM model to rest of design team for coordination.

As the structural consultant, we can provide a BIM model to rest of design team for coordination.

Most effective when we provide both services - structural consulting and steel detailing Model sharing and review is in-house and occurs more frequently

Most effective when we provide both services - structural consulting and steel detailing Model sharing and review is in-house and occurs more frequently

FTP site for the secure transfer of files with clients and suppliers.