Reverse Engineering & Rapid Prototyping

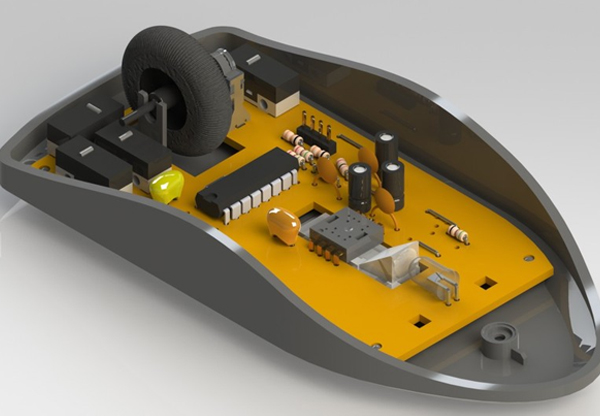

Reverse engineering using 3D scan data is the most efficient way to generate a CAD model from a physical object that has any kind of complex or freeform shape.

While using traditional measurement techniques such as calipers to reverse engineer these complex surfaces can be difficult or even impossible, 3D laser scanning shines - literally! Although this scan data can easily be turned into a model representing its as-built shape (a shrinkwrap model), we specialize in creating models that match original as-designed features - even parametric ones.

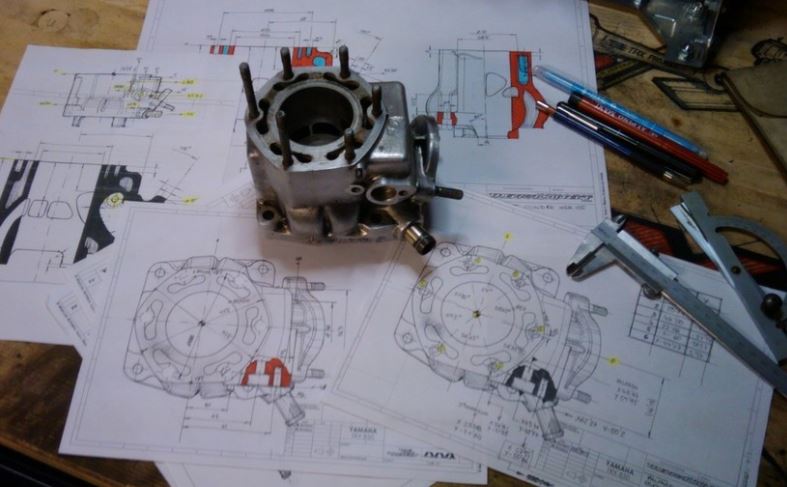

3D scanning is not the "easy button" that many think it is. The most critical step in the reverse engineering process is the modeling bridge performed by the applications engineers. Consequently, the reverse engineering process can be quite complex and is very dependent on the skill and expertise of both the engineers doing the work and those managing the project. Our consultative, problem solving process will help you quantify performance goals and ultimately get you the deliverable you need.

Take advantage of the experience of Intrax’s reverse engineering team to help you:

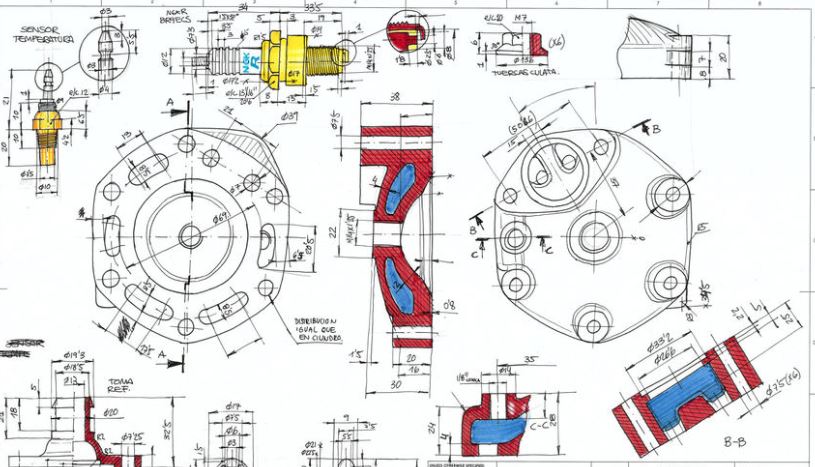

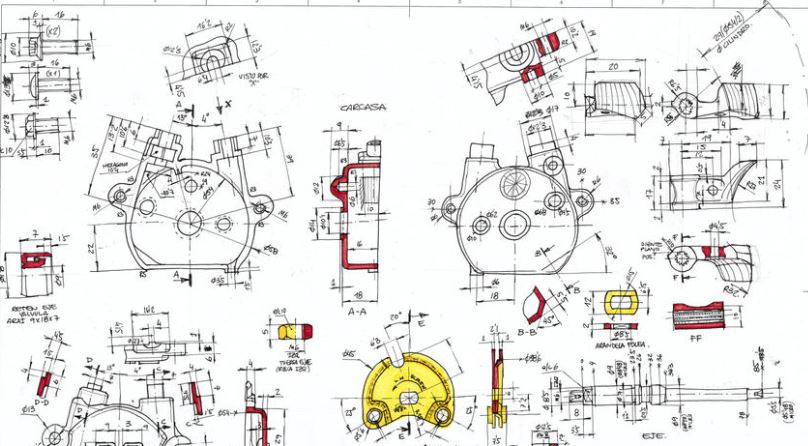

Obtain CAD data that captures an object's original design intent

Obtain CAD data that captures an object's original design intent

Design a new part to fit to a legacy part

Design a new part to fit to a legacy part

Accurately model performance surfaces

Accurately model performance surfaces

Update CAD models of your tooling to match shop-floor changes

Update CAD models of your tooling to match shop-floor changes

Redesign a part without manufacturing defects

Redesign a part without manufacturing defects

Modernize your manufacturing process

Modernize your manufacturing process