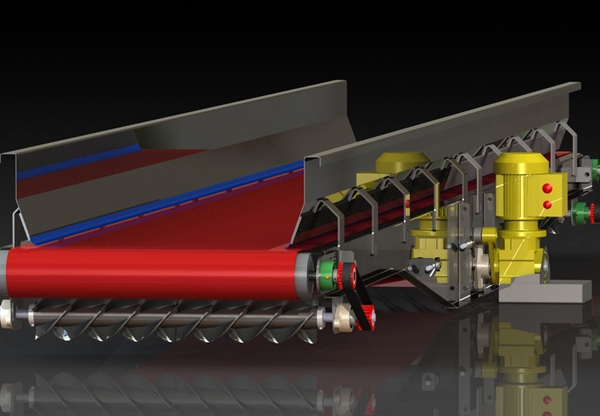

Industrial Machinery

Industrial machinery is unique in every aspect from engineering standpoint. While they seem simple from construction stand point, the design and variety involved is anything but simple. The range of applications for which general industrial machinery is used is limited to one's imagination and this poses a huge challenge to address this vast domain and intricacies that one needs to address while serving this industry. The application can range from special purpose machines, to production equipment, earth moving machinery, printing/packaging machinery, industrial goods and equipments, mechanisms, automation and robotics, jigs and special fixtures, and so on.

Pristine has been working on all the above mentioned and many more areas encompassing this complex domain. Our association with leading engineering organizations while helping them with implementation of latest CAD /CAM /CAE tools helped us picks valuable domain knowledge and develops understanding required to service our customers both in INDIA and overseas. Today Industrial machinery contributes as one of the largest revenue generators for the consulting wing and also attributes to major portion of business from geographies like Europe and South East Asia. Some of the services are

Industrial Machinery CAD Capabilities

Turnkey conceptualization and design of various machines

Turnkey conceptualization and design of various machines

Generation of variants from existing design and new designs based on existing platforms

Generation of variants from existing design and new designs based on existing platforms

Design and development of various mechanisms

Design and development of various mechanisms

Localization of designs as per new markets and geographies. E.g.converting design initially done e.g. for Europe to Indian context using locally available material and standard parts

Localization of designs as per new markets and geographies. E.g.converting design initially done e.g. for Europe to Indian context using locally available material and standard parts

Design automation for repetitive design work by providing customer applications

Design automation for repetitive design work by providing customer applications

Conversion of legacy paper/2d data to parametric 3d models

Conversion of legacy paper/2d data to parametric 3d models

Creating of customer specific part libraries for data reuse and standardization

Creating of customer specific part libraries for data reuse and standardization

Interactive 3D technical documentation for internal and customer use for installation,

Interactive 3D technical documentation for internal and customer use for installation,

commissioning, maintenance and troubleshooting for the equipments

commissioning, maintenance and troubleshooting for the equipments

Industrial Machinery CAE Capabilities

Analysis of various mechanism, multi-body dynamics simulation

Analysis of various mechanism, multi-body dynamics simulation

Weight reduction and optimization studies of components frames etc

Weight reduction and optimization studies of components frames etc

Vibration, thermal and cooling system analysis for sensitive parts and electronics

Vibration, thermal and cooling system analysis for sensitive parts and electronics

CFD and thermal flow simulation

CFD and thermal flow simulation

Validation of loading conditions for equipment like mining, boring and other abusive use

Validation of loading conditions for equipment like mining, boring and other abusive use

Calculations for equipment like pressure vessels, heat exchangers etc to comply with codes and standards

Calculations for equipment like pressure vessels, heat exchangers etc to comply with codes and standards

Establishing code compliance for equipment as per standards required

Establishing code compliance for equipment as per standards required

Seismic, wind, fluid structure interactions for large frames

Seismic, wind, fluid structure interactions for large frames

All Finite element analysis studies including Static, Dynamic, Non-Linear, Buckling,

All Finite element analysis studies including Static, Dynamic, Non-Linear, Buckling,

Transient, Modal, Vibration, Kinematics etc

Transient, Modal, Vibration, Kinematics etc