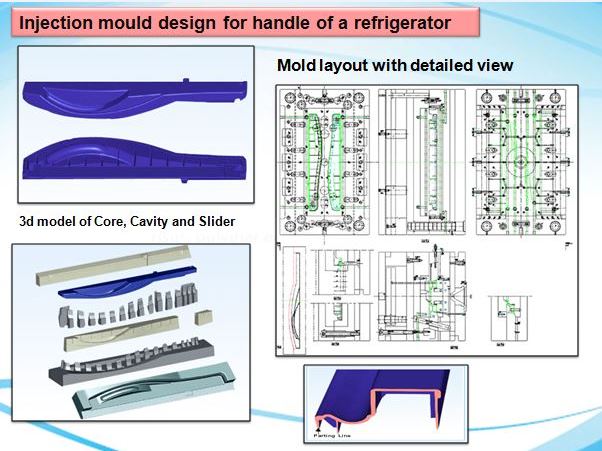

Mold Design

Intrax has a wide ranging and extensive experience in design and manufacture of Dies and Molds for various sectors including Automobile, Furniture, and Electrical Appliances.

Only a limited number of dedicated and reliable platforms are available in the market for the development of complex, high-quality, precision moulds.

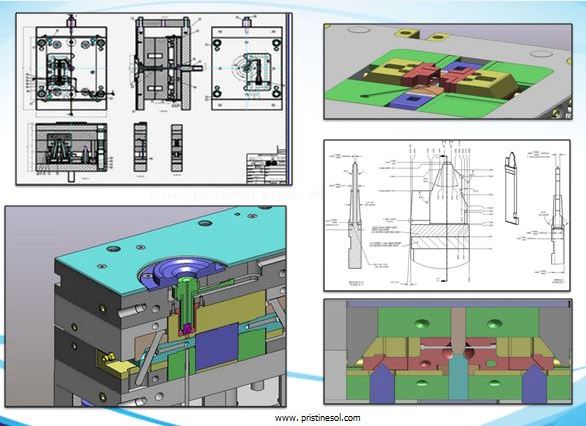

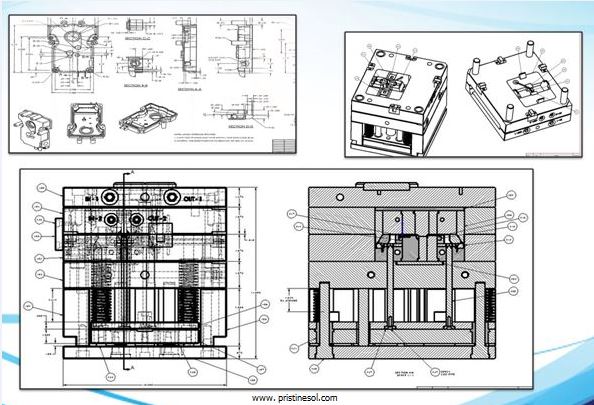

Mold development is initiated on a 3D CAD input and the Base development is undertaken as per DME, HASCO, LKM or any other such standards. Design of Core and Cavity inserts, Moving Cores, Slides and other Components are based on Automatic Parting Line Development. Runners, Gates and Waterlines are positioned as per the material flow analysis.

Ejector system is planned based on the component requirement and incorporated after interference check. Cavity side check for Hot Runner Systems and Hydraulic Systems is also carried out.